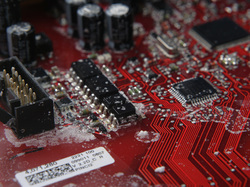

We all think of sunshine when someone mentions the coast, and it's easy to think of PV as being ideally suited for life on the coast. After all, surely you're talking about the sunny South and there's not much to shade it except a few waves, right? This of course is generally true, and a PV system on the coast should be a success. But being on the coast does bring with it a number of challenges, namely sand, salt and the wind. These are of course problems that any structure needs to face, but that doesn't mean they can be ignored - indeed, since many installation crews work all over the UK, it's often completely forgotten. I've just put together a specification for a 250kWp array on a new industrial unit in Cornwall, and with this in mind, here are some of the design considerations I bore in mind:  The air on the coast is much more salty than "usual" - we all know the smell of the sea - and this can accelerate electrolytic corrosion of metals. Any equipment installed on the coast should allow for this; ask for modules and inverters with salt mist test certification. The IP rating alone won't tell you this, as salt is a particularly corrosive substance that will get through seals over time. The photo on the left shows the power circuit board of a Fronius inverter that has been through this test. This particular manufacturer has lacquered the circuitry so despite a relatively low IP rating, components will still function if salt gets in. Other products may rely on a hermetic seal... But will that seal last 25 years? Make sure it's been tested!  The rest of the structure can be affected too. The array mounting structure will be exposed to the hostile environment so choosing materials carefully - and avoiding electrically dissimilar metals - is a definite action point. Untreated steel will probably rust, whereas alumninium and stainless steel should last longer. Using an inverter without a transformer will, by design, result in a leakage current to true earth. As can be seen in the attached photo, this leakage will affect even inland systems and you'll get accelerated corrosion (the system is less than a year old but there's a distinct patch of oxidation visible already and the copper fitting is already "rusting"). As seen in the photo, inland this is normally within accetable limits, but when on the coast there's already an increased risk so consider including a transformer for galvanic isolation to minimise this effect. This also applies to other exposed metalwork, such as cable mounting systems (choose stainles steel or coated) and the building itself. Even if the PV components are tough enough, will it affect more delicate cladding and finishes? On top of all the salt in the air, you've got to contend with sand too. The array itself should be fine as long as it's at a sufficient angle to prevent sand piling up. On the other hand, sand, as with any other fine particle, does have a habit of clogging filters and fans. Again, this is where quality equipment comes into play: High end manufacturers such as SMA and Fronius separate the cooling air channel from the components themselves. However, the fans pulling this air through can still get blocked and/or be abraded by the sand, so consider where the inverters are to be kept, and whether an additional filter would help. Finally, there's the stronger wind that you normally get on coastal sites. While this is rarely a problem - at least in the UK where it's relatively docile - it should be accounted for in the fixing design. This is a factor included in designs in accordance with the MCS code MIS3002 and the Eurocode range (BS EN 1991), and should be done by your installation company by default.  In summary, installing PV near the coast does have additional challenges. But none of these challenges are insurmountable, and a well designed installation will perform as well as any other in the UK - if not better. (Thanks to SMA and Fronius for some of these images)

0 Comments

Leave a Reply. |

News

Industry news and comment, as well as company announcements, by James, our Company Director Archives

September 2021

Categories |

RSS Feed

RSS Feed